Weld Overlay Wear Plates

DURAPEX delivers complete, tailored wear solutions to meet the specific demands of your operations.

Leveraging our expertise in high-performance wear plates, we provide the right materials for every application—whether your equipment faces severe abrasion, high-impact conditions, or challenging material handling environments.

Our durable wear plates are engineered to maximize service life, minimize downtime, and optimize operational efficiency, ensuring reliable performance and long-term protection for your critical equipment.

Factory Quality Assurance

At DURAPEX, every wear plate is produced under strict control using our advanced production management system, with rigorous quality checks from raw material inspection to final testing. This ensures full traceability, consistent performance, and long-term reliability, delivering wear solutions our customers can trust across even the most demanding industrial applications.

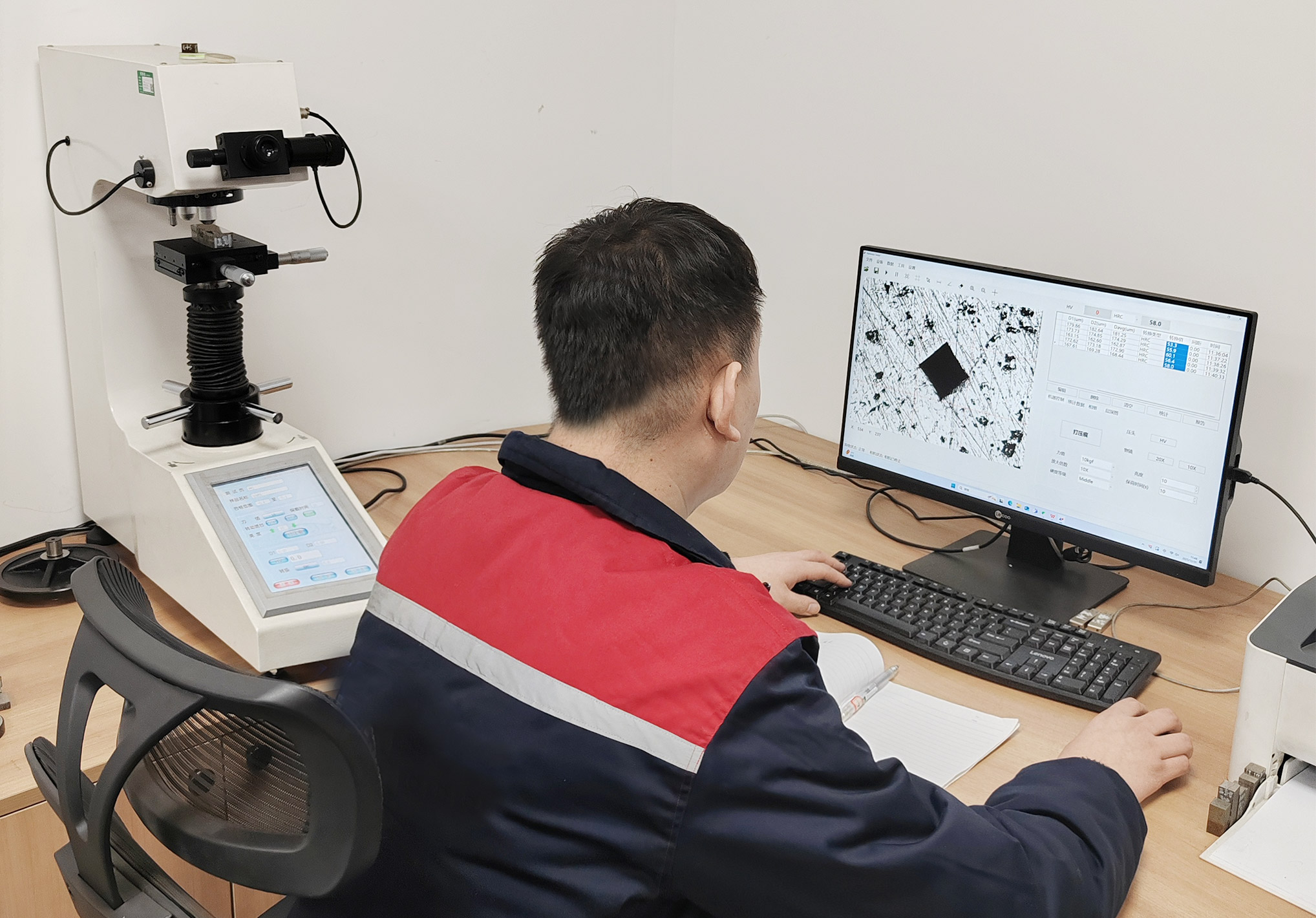

Quality Verification & Testing

At DURAPEX, quality is verified through systematic testing and inspection, ensuring every wear plate meets performance expectations before delivery. Our quality assurance process includes hardness testing, chemical composition analysis, surface inspection, and weld integrity verification, confirming material integrity, wear resistance, and consistency for demanding industrial applications

Hardness

Chemical Composition Analysis

Surface & Dimensional Inspection

Wear Performance ASTM-65 procedure A

DURAPEX INDUSTRIAL

DURAPEX is a professional manufacturer and solution provider of chromium carbide overlay

(CCO) wear plates, dedicated to delivering reliable wear protection for demanding

industrial

applications.

With a strong focus on process control, product consistency, and

quality

assurance, DURAPEX operates under a structured production management system that ensures

every wear plate is manufactured, inspected, and delivered to defined standards. From

raw

material selection to final acceptance, each step is carefully controlled to guarantee

stable performance and long service life.

Our team combines experienced technical

personnel, verified welding procedures, and disciplined quality systems to support

customers

in mining, cement, power generation, steel, and bulk material handling industries.

Backed by

full traceability and systematic testing, DURAPEX wear plates provide dependable

solutions

where wear resistance and operational reliability matter most.

Durapex

2025

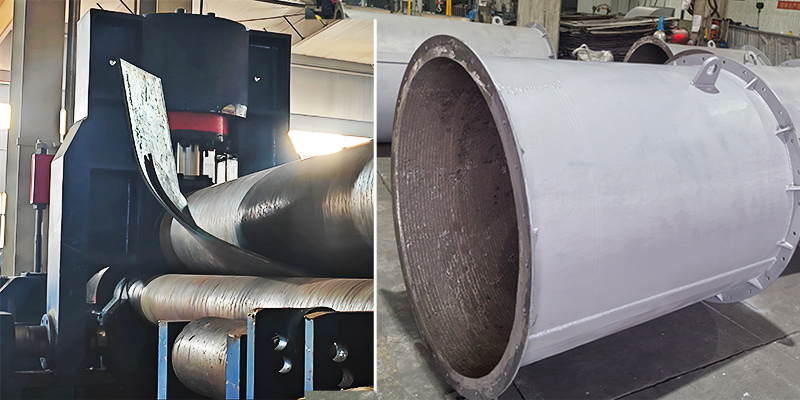

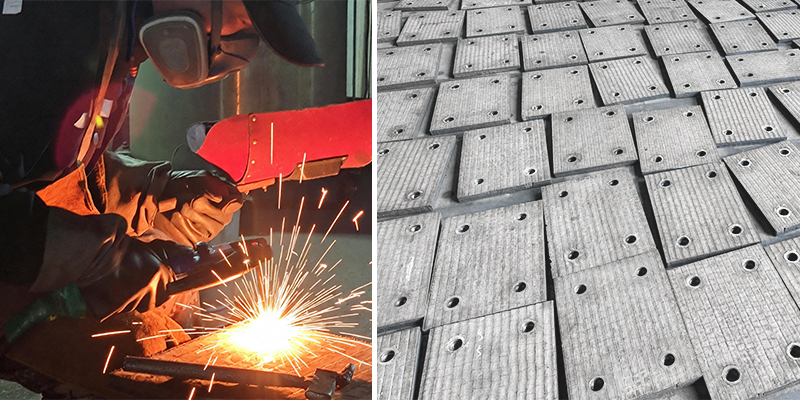

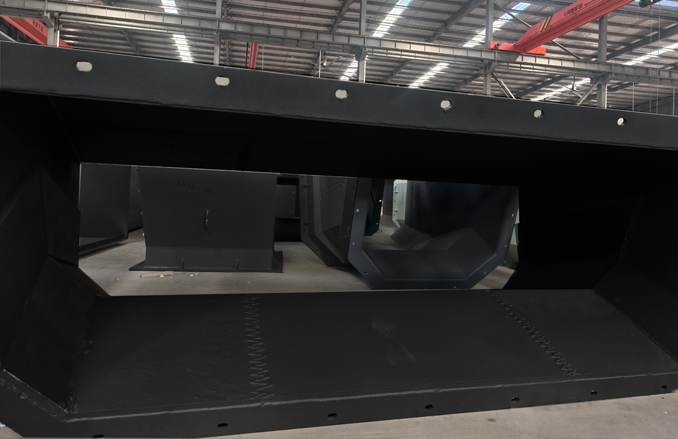

Fabrication & Wear Solution Engineering

DURAPEX provides professional fabrication services designed specifically for chromium

carbide

overlay wear plates. All cutting, forming, and preparation processes are carefully

controlled to preserve the integrity of the wear layer and ensure consistent performance

in

service.

Beyond fabrication, our engineering team supports customers with application-oriented

solutions — supplying wear plates in the right grade, thickness, and configuration to

match

actual operating conditions. Pre-fabricated liners and components help reduce on-site

installation time, minimize maintenance downtime, and improve overall equipment

reliability.

Whether supplying flat plates or custom-fabricated wear parts, DURAPEX ensures every

solution is engineered for durability, fit, and long-term wear resistance.

Plasma and laser cutting up to 30mm thickness

Rolling & forming for pipes and liners

Submerged arc overlay rebuilding

Machining and drilling services

Industries We Serve

DURAPEX delivers engineered wear solutions for industries operating under severe abrasion, impact, and high-load conditions. By understanding real operating environments, we provide wear plates and fabricated solutions that extend service life, reduce downtime, and improve equipment reliability across a wide range of industries.

LATEST NEWS

In critical coal transportation scenarios such as coal mines, power plants, and ports, the chute serves as the core hub connecting high-level unloading and low-level conveying systems. Its performance directly impacts the operational stability of the entire system. Traditional chutes have long faced prominent issues such as frequent coal clogging, excessive wear, severe dust emission, and material impact. These problems not only hinder efficiency but also pose ongoing threats to on-site safety and continuous production.

ISO Certified Management System

DURAPEX operates under an ISO-certified management system that governs every stage of production — from material control and welding procedures to inspection, documentation, and final delivery.

This structured system ensures consistent quality, process discipline, and reliable performance across every batch, giving customers confidence in long-term supply stability and product integrity.