Tianjin Durapex Industrial

Tianjin Durapex Industrial

Email:

Phone:

Address:

DF‑V is a vanadium‑modified fused alloy plate that offers a versatile balance of abrasion resistance and impact toughness. Vanadium additions refine carbide structure and improve wear resistance across a broad range of operating conditions.

| Grades | Typical Harndess | C | Cr | Mn | Si | Mo+Nb+V+Ti | V | W | Other |

| DF-Cr | HRC58-63 | 3.5-6.5 | 25-40 | 0.5-2.5 | 0.5-2.5 | – | – | – | – |

| DF-M | HRC58-63 | 3.5-6.5 | 25-40 | 0.5-2.5 | 0.5-2.5 | 2.5-14 | – | – | – |

| DF-T | HRC58-63 | 3.5-6.5 | 25-40 | 0.5-2.5 | 0.5-2.5 | – | – | 2.0-7.0 | – |

| DF-V | HRC58-63 | 3.5-6.5 | 25-40 | 0.5-2.5 | 0.5-2.5 | 3.0-6.0 | – | – |

| Base plate | Overlay | Thickness(Base+Overlay) | Standard Dimensions |

| 5 | 5 | 5+5 | 1000*3500

1000*3000 |

| 5 | 6 | 5+6 | |

| 7 | 8 | 7+8 | |

| 10 | 10 | 10+10 | |

| 12 | 12 | 12+12 | |

| 12 | 25 | 12+25 | |

| 16 | 32 | 16+32 |

Superior sliding abrasion resistance and long service intervals.

Low friction surface reduces carry‑back and spillage.

Bead‑free finish option for improved material flow.

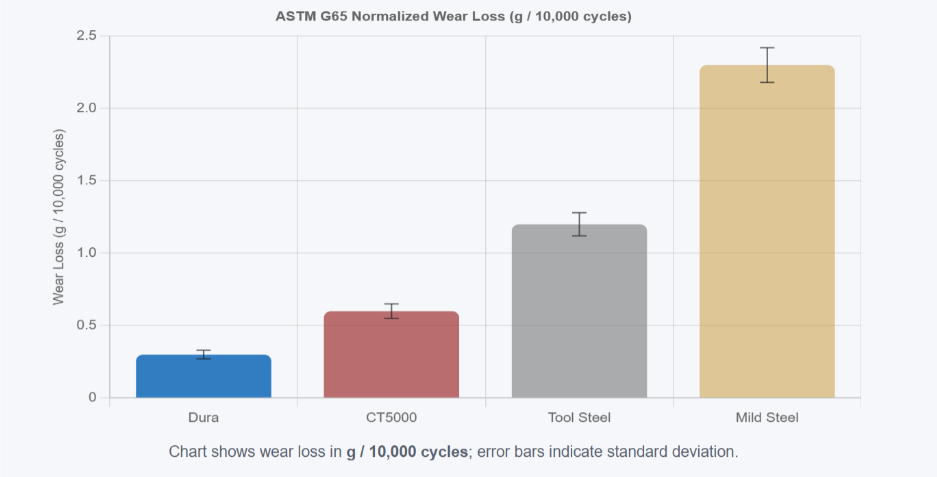

Excellent Wear Performance under G65 Procedure A.

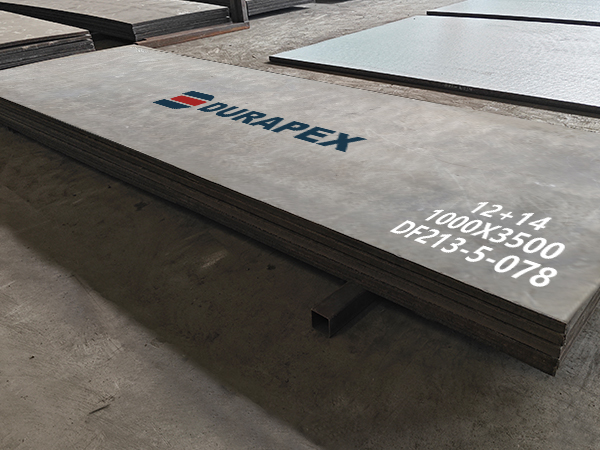

Each DF-V wear plate is assigned a unique plate identification number supported by our proprietary grading system. This ensures full traceability, consistent quality control, and clear differentiation across all production batches.

Plate Scroring

Unique Plate ID

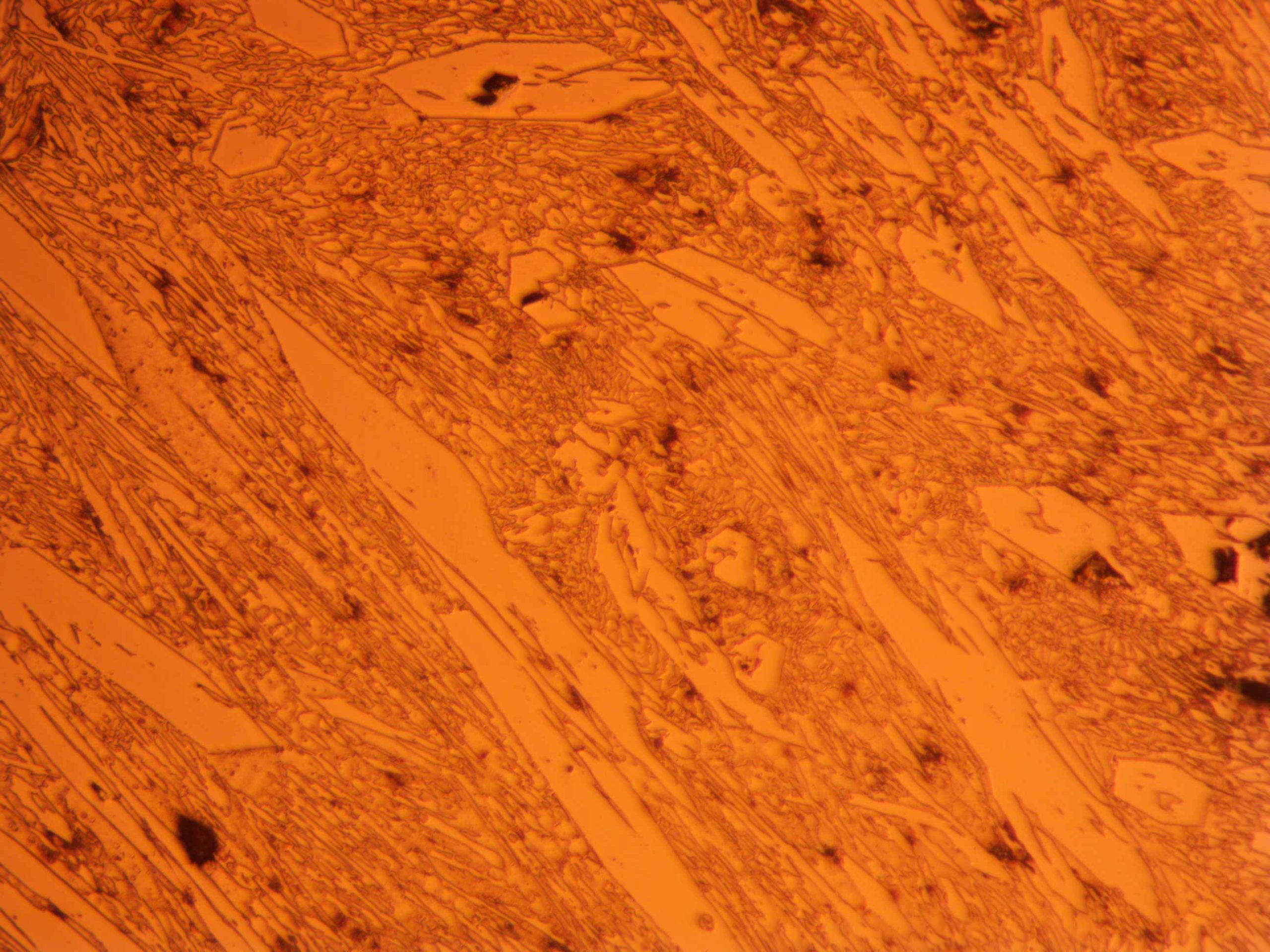

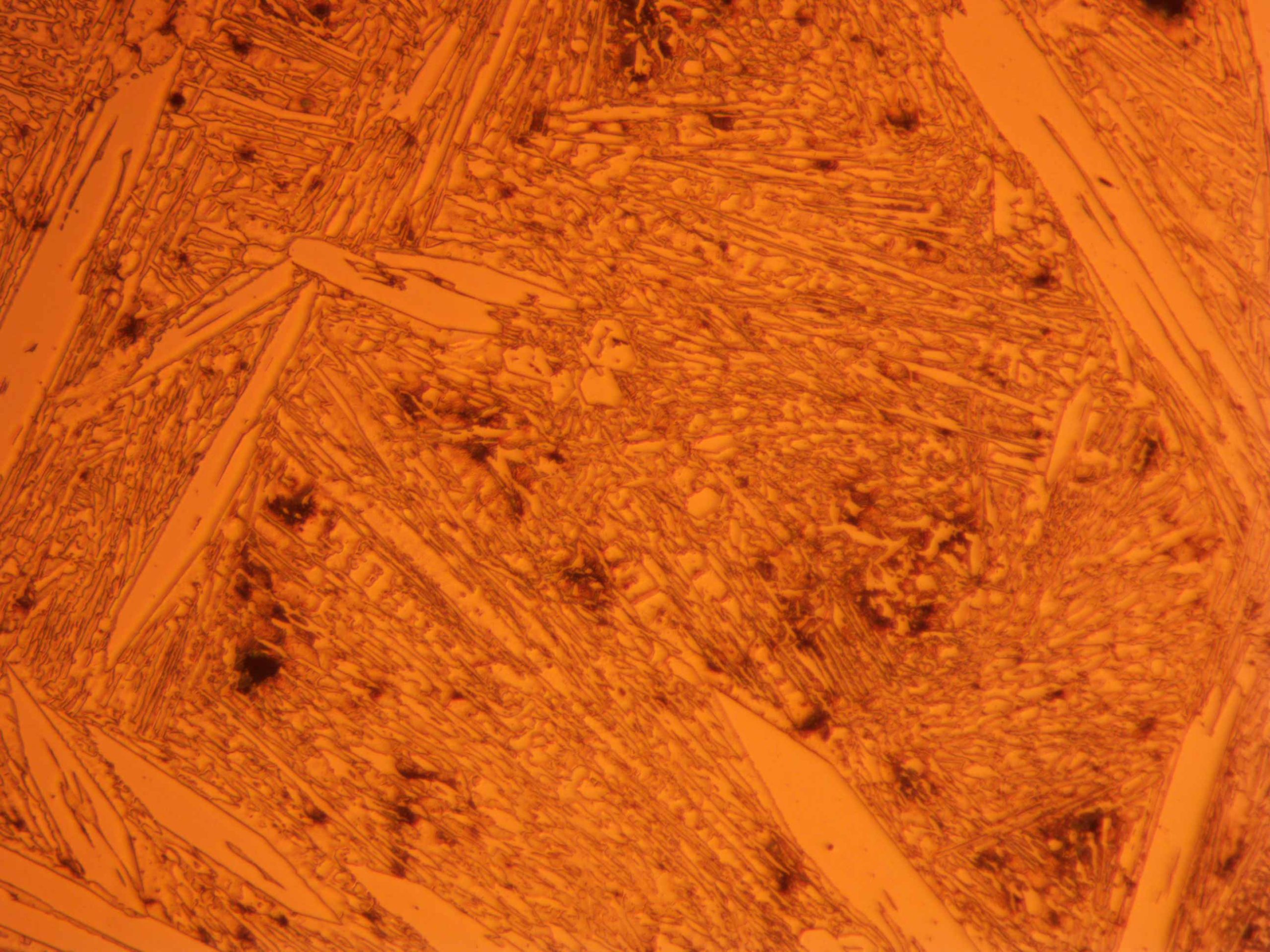

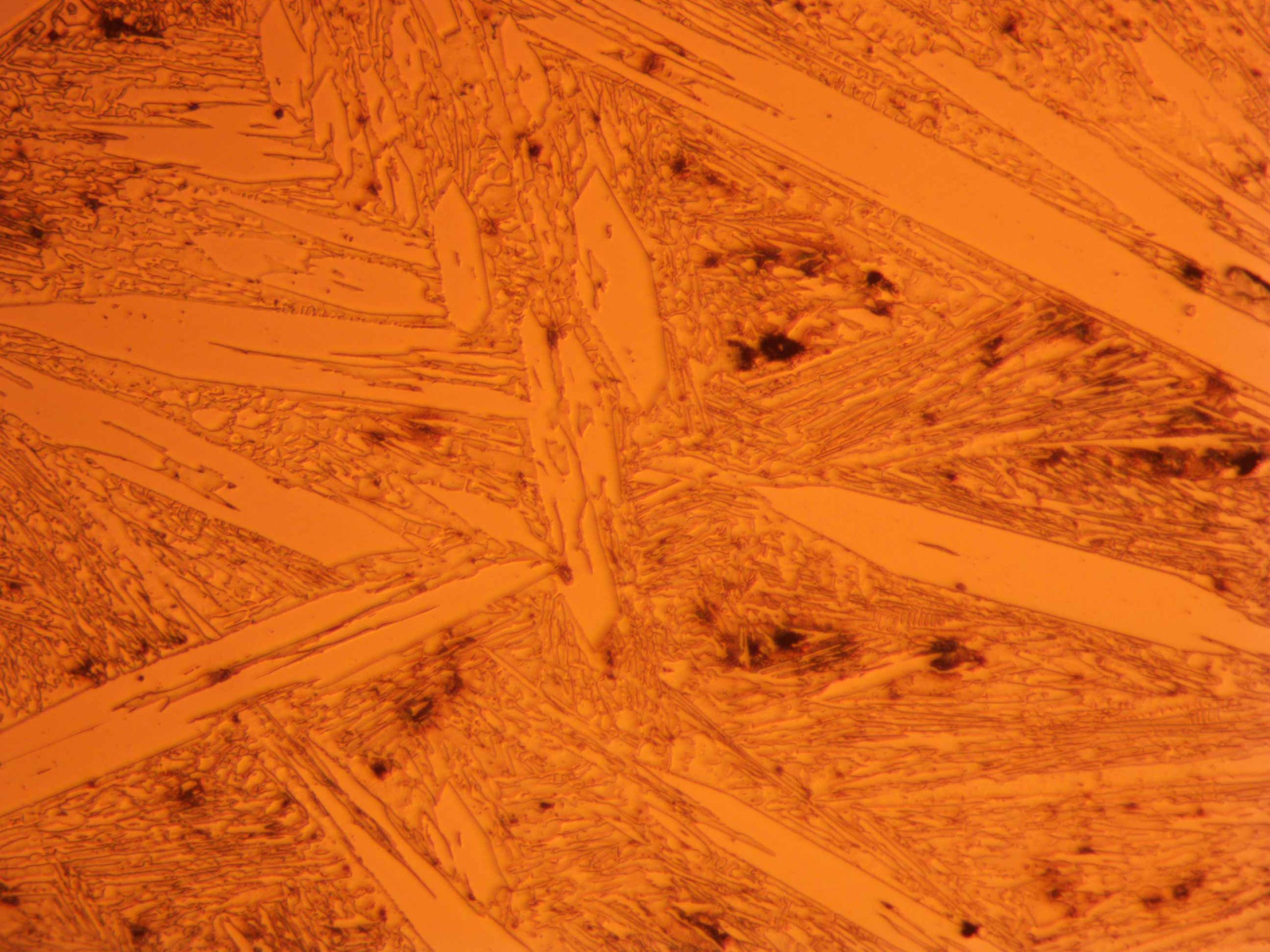

The microstructure of DF-V consists of a high proportion of extremely hard primary M₇C₃ chromium‑rich carbides, typically reaching about 1200–1500 HV, evenly distributed within a tough eutectic austenitic matrix. The primary carbide volume fraction is controlled between 30% and 50% to ensure an optimal balance of wear resistance and consistent metallurgical bonding.

DF-V has been tested according to ASTM G65 Procedure A, demonstrating excellent resistance to severe sliding abrasion with significantly lower volume loss compared to conventional wear plates.

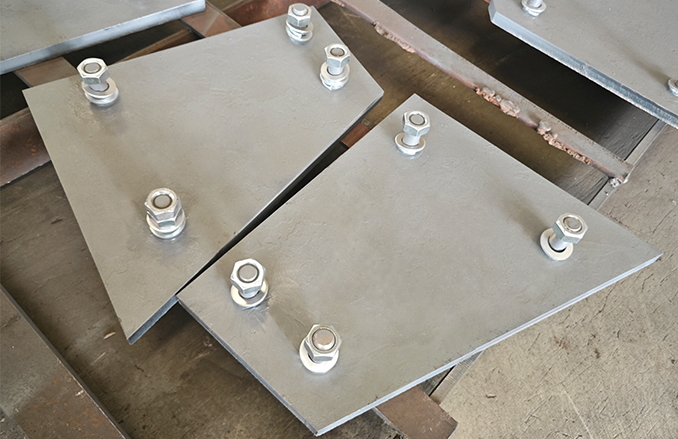

DF-V plates maintain structural integrity during fabrication, regardless of shape or complexity. We provide complete processing services—cutting, forming, welding, stud attachment, assembly, and grinding—delivering ready-to-install wear parts tailored to your needs.

Accurate plasma or oxy‑fuel cutting according to your drawings, including complex shapes, bolt holes, and edge preparations for efficient installation.

Rolling and forming of CCO plates for cones, pipes, and curved liners, helping you handle material flow in chutes, cyclones, and ducts.

Plates can be prepared with beveled edges for welding and bolting for easy mounting, providing flexible installation options.

Fabrication of complete liner packages and assemblies based on your design, enabling plug‑and‑play installation during scheduled shutdowns.

DF-V is extensively applied across heavy industries including mining, power generation, cement, dredging, steelmaking, waste management, glass manufacturing, and pulp and paper. Typical applications include:

Mining: Chutes, hoppers, truck bed liners, dozer blades, shovel buckets, dragline buckets, excavator components

Cement: Separator guide vanes, clinker bin discharge cones, sintering ore chutes, clinker mill outlet ducts, receiving hoppers

Dredging: Dredging pipes and pumps, suction pipelines, pump discharge sections

Steelmaking: Fan blades and housings, vibrating screen plates for coke handling

Power Generation: Coal chutes, feeder liners, crusher screen plates, classifier cones, journal liners, silo bunkers

All DURA-ARC products are produced under ISO 9001, 14001 and 45001 with full plate-level traceability. Each plate receives a unique ID linking to its weld-pass records, hardness map and test reports.

Example Plate ID: D100-20251016-001 — traceable to overlay batch, operator, and test files.