Tianjin Durapex Industrial

Tianjin Durapex Industrial

Email:

Phone:

Address:

DS-SAW plates are premium submerged arc weld overlay wear solutions engineered for severe abrasion and impact. Featuring a dense carbide-rich overlay metallurgically bonded to structural steel, they deliver consistent wear life, reduced maintenance downtime, and lower cost-per-ton performance. Optimized for sliding abrasion and moderate impact, DS-Series plates maintain reliable performance even under elevated temperatures and heavy material flow. Available in multiple grades, thicknesses, and configurations, they are widely used in mining, cement, steelmaking, and bulk material handling applications.

Dura-Saw offers multiple grades, each engineered for specific wear environments, along with fully custom solutions to meet unique operational requirements.

| Grade | Core Composition | Key Performance |

| DF100 | Chromium Carbide-Rich Overlay | Maximum abrasion resistance |

| DF200 | Composite Carbides Matrix | Superior toughness; thermal stability; impact resistance |

| DF300 | Tungsten Carbide-Reinforced | Extreme wear resistance at elevated temperature |

| DF100H | An upgraded version of DS-100 | Enhanced microstructure of DS-100 |

Tailored carbide formulations as per request.

Dense carbide-rich overlay resists sliding abrasion, impact, and material carry-back. Uniform hardness ensures predictable service life.

Weld-bead-free, polished surfaces reduce friction, prevent material hang-up, and minimize spillage.

Non-directional plates fit any orientation. Ideal for mining, bulk handling, power generation, and heavy industrial equipment.

Stress-relieved plates withstand severe bending, dynamic loads, and high-impact conditions without cracking or spalling.

Every Dura-SAW plate is manufactured under strict quality control using our advanced production management system. From raw material inspection and welding trials to final testing, each plate is fully traceable, rigorously scored, and certified to ensure consistent performance and long-term reliability.

Continuous inspection during each overlay pass, with hardness mapping and thickness verification for every plate.

Each DURA-SAW plate has a unique ID, fully traceable to its manufacturing, welding, and test records.

We provide in-house services from cutting to assembly, preserving overlay integrity and dimensional accuracy.

Accurate plasma or oxy‑fuel cutting according to your drawings, including complex shapes, bolt holes, and edge preparations for efficient installation.

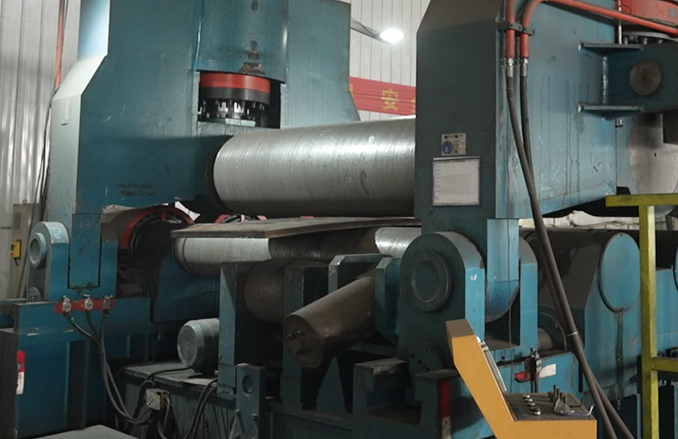

Rolling and forming of CCO plates for cones, pipes, and curved liners, helping you handle material flow in chutes, cyclones, and ducts.

Plates can be prepared with beveled edges for welding and bolting for easy mounting, providing flexible installation options.

Fabrication of complete liner packages and assemblies based on your design, enabling plug‑and‑play installation during scheduled shutdowns.

A: DS‑SAW CCO plates are submerged arc weld overlay wear plates featuring a dense chromium‑carbide or complex‑carbide overlay metallurgically bonded to structural steel. They are engineered for severe sliding abrasion and moderate impact, delivering consistent wear life across demanding industrial applications.

A: DS‑SAW100 is the standard chromium‑carbide overlay grade for high abrasion and low impact.

DS‑SAW100H is the enhanced version with improved performance under elevated temperatures and more aggressive wear conditions.

DS‑SAW300 is a complex‑carbide or tungsten‑carbide reinforced grade designed for extreme abrasion and moderate impact, including applications requiring BHP Composition 3 compliance.

A: Yes. DS‑SAW plates can be supplied in various thicknesses, grades, and formats, including flat sheets, formed sections, and precision‑cut components. Custom configurations are available for mining, cement, steelmaking, power generation, and other heavy‑duty industries.

Our facilities are ISO certified in Safety, Environment & Management System.